OUR PRODUCTS

hidroresin offers a wide range of water-soluble resins made of polyvinyl alcohol (PVA) engineered to offer biodegradable solutions across multiple industries.

PRODUCTS

PROCESSING METHODS

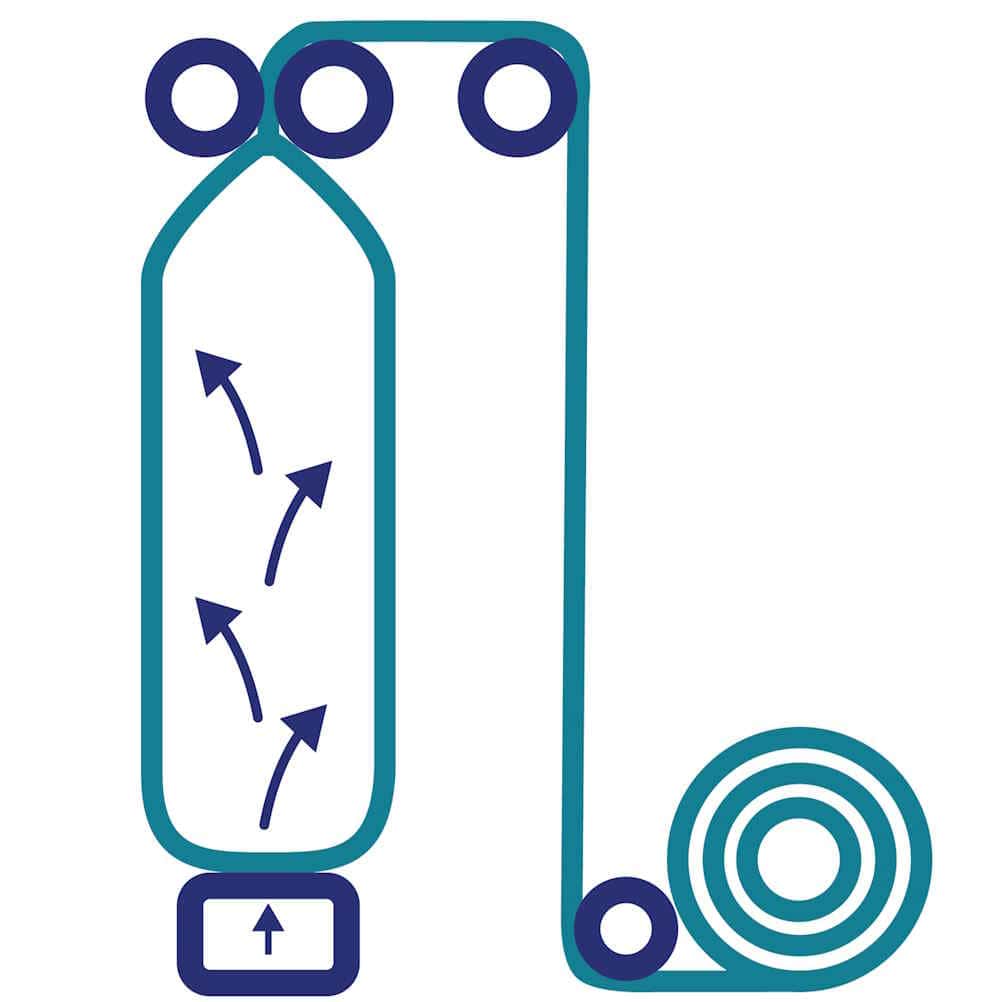

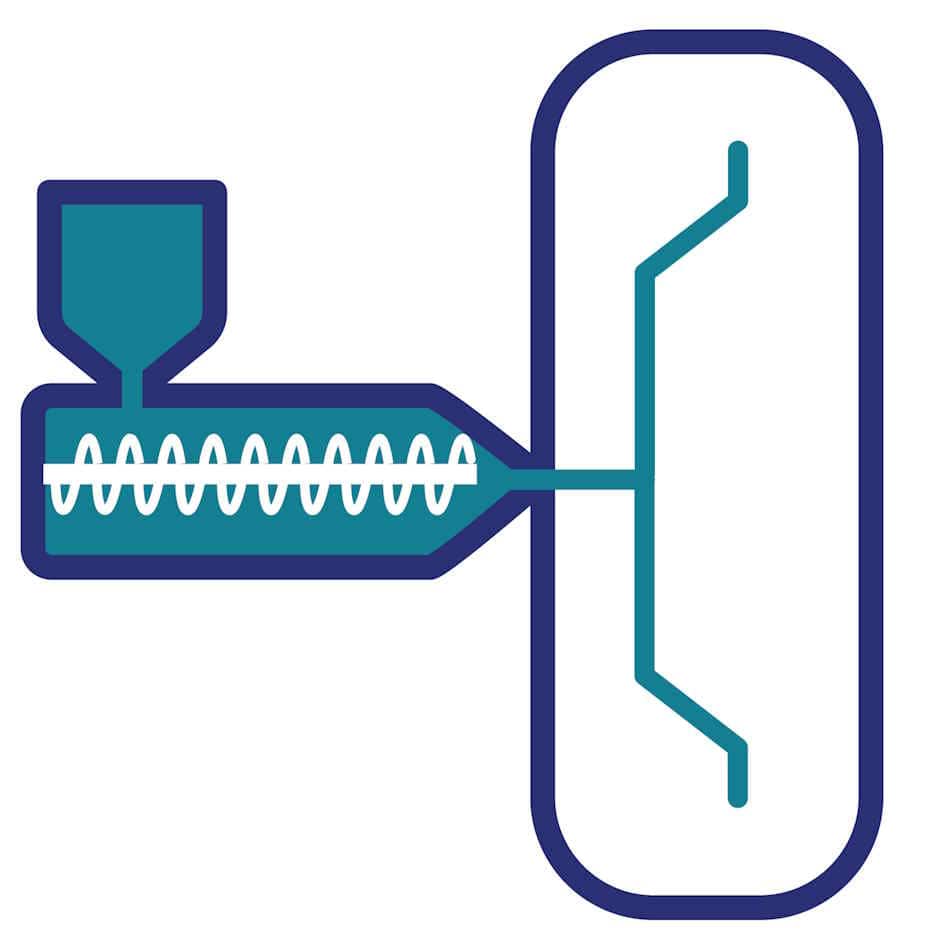

hidroresin water soluble plastic offers versatility in processing through a range of methods, allowing for tailored solutions to meet specific requirements.

PROCESSING

BLOW EXTRUSION

BLOW MOULDING

INJECTION MOULDING

EXTRUSION MOULDING

3D

PRINTING

BLOW EXTRUSION

BLOW MOULDING

INJECTION MOULDING

EXTRUSION MOULDING

3D

PRINTING

ADVANTAGES

hidroresin have exceptional functionality while remaining recyclable and ecologically harmless, making them an excellent alternative to traditional and/or compostable plastics.

ADVANTAGES

APPLICATIONS

hidroresin water soluble plastic offers versability and unique properties, these resins can be employed in the creation of extensive range of items.

APPLICATIONS

WATER SOLUBLE CARTRIDGES

WATER SOLUBLE CAPSULES

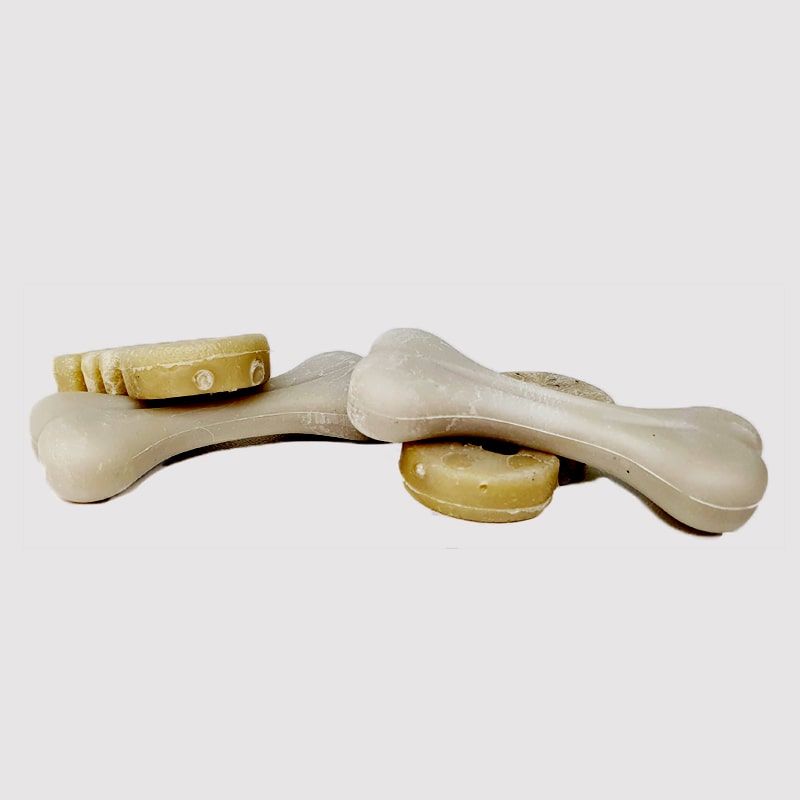

WATER SOLUBLE TOYS

WATER SOLUBLE PIECES

WATER SOLUBLE BOXES

WATER SOLUBLE CONTAINERS

WATER SOLUBLE LIDS

WATER SOLUBLE HANGERS

WATER SOLUBLE BAGS

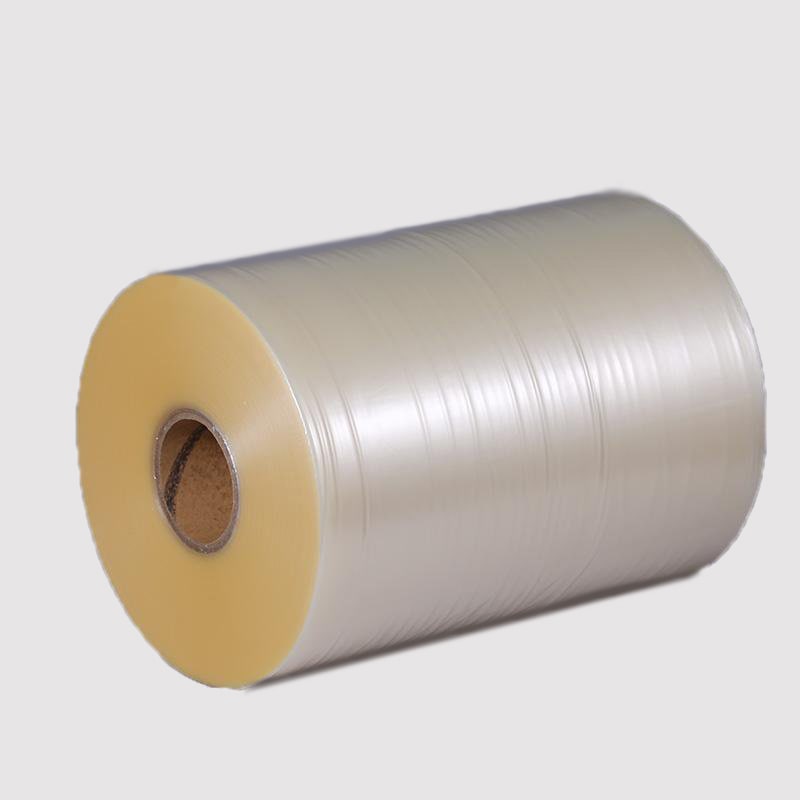

WATER SOLUBLE FILM

WATER SOLUBLE PLUGS

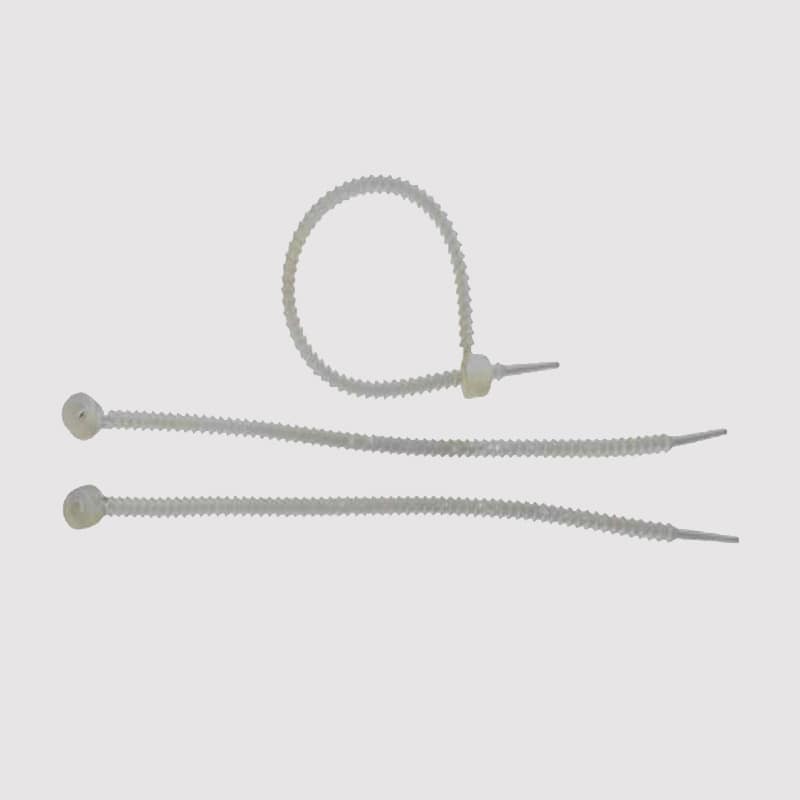

WATER SOLUBLE SEALS

RESEARCH & DEVELOPMENT

We work together with LMPE in the development and research of innovative polymer formulas that consider both environmental aspects and viability in economic and technical terms, without neglecting the quality and reliability of the final product. We have more than 30 years of proven experience in developing innovations based on polyvinyl alcohol (PVA).

RESEARCH & DEVELOPMENT

We work together with LMPE in the development and research of innovative polymer formulas that consider both environmental aspects and viability in economic and technical terms, without neglecting the quality and reliability of the final product. We have more than 30 years of proven experience in developing innovations based on polyvinyl alcohol (PVA).

FAQS

Water-soluble resins dissolve completely upon contact with water and undergo natural decomposition into water and carbon dioxide when consumed by bacterial microorganisms. Extensive research has demonstrated that a wide array of naturally occurring microorganisms can effectively degrade PVA without leaving any harmful residues behind.

Various research studies have indicated that PVOH does not contribute to the generation of microplastics.

Yes. Polyvinyl alcohol (PVOH) is regarded as potentially recyclable; however, its recyclability is contingent upon various factors. These factors encompass the local recycling infrastructure, collection systems in place, and the existence of recycling processes capable of handling PVOH

PVA is renowned for its non-toxic properties, making it a safe choice for various applications. It finds extensive use in packaging for household and food products, medical applications such as capsule and tablet coatings, and as a component in artificial tears. Additionally, PVA plays a role in the cosmetic sector by facilitating the blending of chemical components. Toxicological studies have consistently demonstrated the minimal absorption of this substance by the human body, leading to its approval for oral consumption. This safety profile reinforces the widespread use of PVA across industries, ensuring the well-being of consumers and patients alike.

PVA can undergo degradation through multiple mechanisms, including photothermal, oxidation, and biological processes. Research studies have demonstrated that a diverse range of microorganisms, including at least 20 different types of bacteria, as well as various molds and yeasts, possess the capability to break down PVA. These microbial and biochemical attacks result in the conversion of PVOH into environmentally benign byproducts, including carbon dioxide, water, and biomass. This natural degradation process underscores the eco-friendly nature of PVA and its minimal impact on the environment.

PVOH, or Polyvinyl Alcohol, is a synthetic organic polymer derived from polyvinyl acetate through a process known as hydrolysis. During hydrolysis, the acetate groups in polyvinyl acetate are replaced with hydroxyl groups (-OH), resulting in the formation of PVOH. One of its distinctive characteristics is its water solubility, making it readily dissolvable in aqueous environments. Additionally, PVOH is biodegradable when exposed to water, further contributing to its eco-friendly properties.

FAQ

Water-soluble resins dissolve completely upon contact with water and undergo natural decomposition into water and carbon dioxide when consumed by bacterial microorganisms. Extensive research has demonstrated that a wide array of naturally occurring microorganisms can effectively degrade PVA without leaving any harmful residues behind.

Various research studies have indicated that PVOH does not contribute to the generation of microplastics.

Yes. Polyvinyl alcohol (PVOH) is regarded as potentially recyclable; however, its recyclability is contingent upon various factors. These factors encompass the local recycling infrastructure, collection systems in place, and the existence of recycling processes capable of handling PVOH

PVA is renowned for its non-toxic properties, making it a safe choice for various applications. It finds extensive use in packaging for household and food products, medical applications such as capsule and tablet coatings, and as a component in artificial tears. Additionally, PVA plays a role in the cosmetic sector by facilitating the blending of chemical components. Toxicological studies have consistently demonstrated the minimal absorption of this substance by the human body, leading to its approval for oral consumption. This safety profile reinforces the widespread use of PVA across industries, ensuring the well-being of consumers and patients alike.

PVA can undergo degradation through multiple mechanisms, including photothermal, oxidation, and biological processes. Research studies have demonstrated that a diverse range of microorganisms, including at least 20 different types of bacteria, as well as various molds and yeasts, possess the capability to break down PVA. These microbial and biochemical attacks result in the conversion of PVOH into environmentally benign byproducts, including carbon dioxide, water, and biomass. This natural degradation process underscores the eco-friendly nature of PVA and its minimal impact on the environment.

PVOH, or Polyvinyl Alcohol, is a synthetic organic polymer derived from polyvinyl acetate through a process known as hydrolysis. During hydrolysis, the acetate groups in polyvinyl acetate are replaced with hydroxyl groups (-OH), resulting in the formation of PVOH. One of its distinctive characteristics is its water solubility, making it readily dissolvable in aqueous environments. Additionally, PVOH is biodegradable when exposed to water, further contributing to its eco-friendly properties.

CONTACT US

CONTACT US

EUROPE

VALENCIA – SPAIN

ASIA

HONG KONG – CHINA

LATIN AMERICA

MONTEVIDEO – URUGUAY

MEXICO

MEXICO D.F. – MEXICO